From what aspects to improve the level of sheet metal processing technology

The traditional sheet metal processing industry in China has developed dozens of years, but with the progress of society and technology, there is a new processing technology and large advanced equipment introduced from abroad, many traditional profile laser processing factories are faced with the problem is the shortage of technical personnel form a complete set of processing equipment, backwardness and imperfect, single sales channel, conservative is not innovation, etc. This makes many sheet metal processing enterprises to bottleneck or face the risk of bankruptcy.

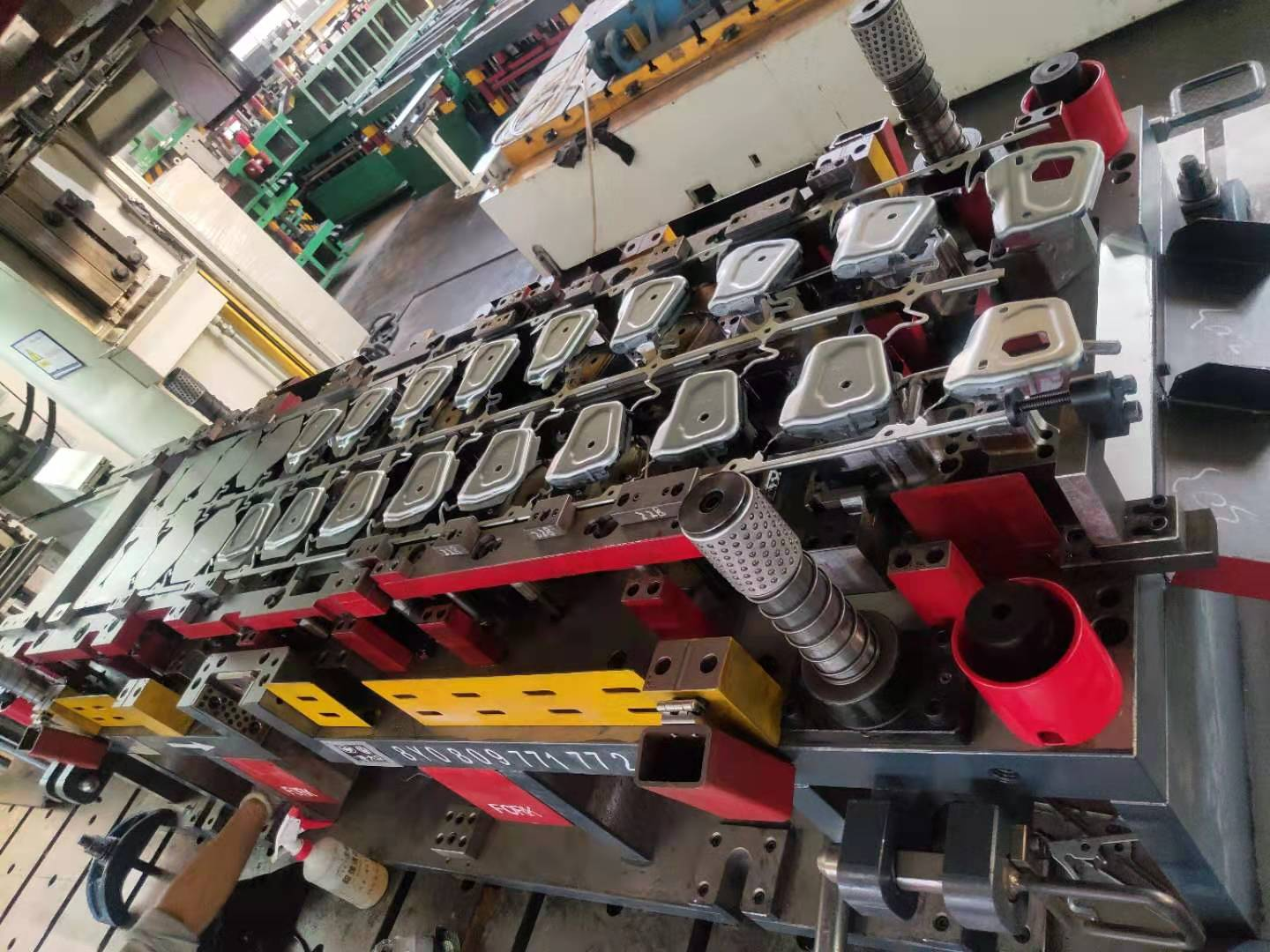

Sheet metal processing is the process of a number of metal sheet by hand or die stamping to produce plastic deformation to the desired shape and size, and can be further through welding or a small amount of machining to form more complex parts. This process plays an important role in mechanical production. So, how can we improve the level of sheet metal processing technology? We need to pay attention to these aspects:

1, the standardization of sheet metal processing principle. Tools, jigs and workpieces should not be placed on the lathe or on the gearbox. You need to concentrate on the construction. No fatigue, chatting, multiple people or smoking manipulation. In order to prevent chippings from hitting people, transparent baffles need to be placed in suitable places. In the cutting of the strip chip, sheet metal processing shape of long chip, need to use hooks as soon as possible to solve, can not be pulled by hand. When it is suitable for grinding the appearance of parts with gauze, it is necessary to move the tool to a safe place, and be careful not to let the hands and clothes touch the appearance. When grinding the holes inside, do not use your finger to support the gauze. You need to use other items instead, and the speed should not be too fast.

2, strengthen the research of sheet metal processing technology. The change rules of strain and size of components in plastic forming process of sheet metal processing are studied, and the suitable blank and reasonable center blank shape are selected so as to better reach the required shape of components. To study the influence of temperature, strain rate effect and other sheet metal working conditions on metal plastic working resistance, and to improve the metal resistance and reduce the resistance, in order to obtain the components with outstanding functions.

In the actual production process, enterprises due to their own constraints, the degree of automation is not advanced, low processing efficiency, manpower consumption, if the design and use of appropriate tooling, the production of workpiece mass, streamlining, can greatly improve this phenomenon. In actual production, the work of CNC bending group in machining workshop is the key and difficult point of the department. In order to improve production efficiency and product quality, and actively guarantee supply, the staff of the department often need to work a large shift every day to increase production by increasing production time.

推荐资讯 / Recommended News

Contact Us

Qingdao Yusen Precision Industry Co., Ltd

Contact person: manager Chen

Mobile: 18953226137

Email: quality@qdyusen.cn

business@qdyusen.cn

Address: Jiefang Third Road, Longquan automobile industry new town, Jimo District, Qingdao

CN

CN EN

EN