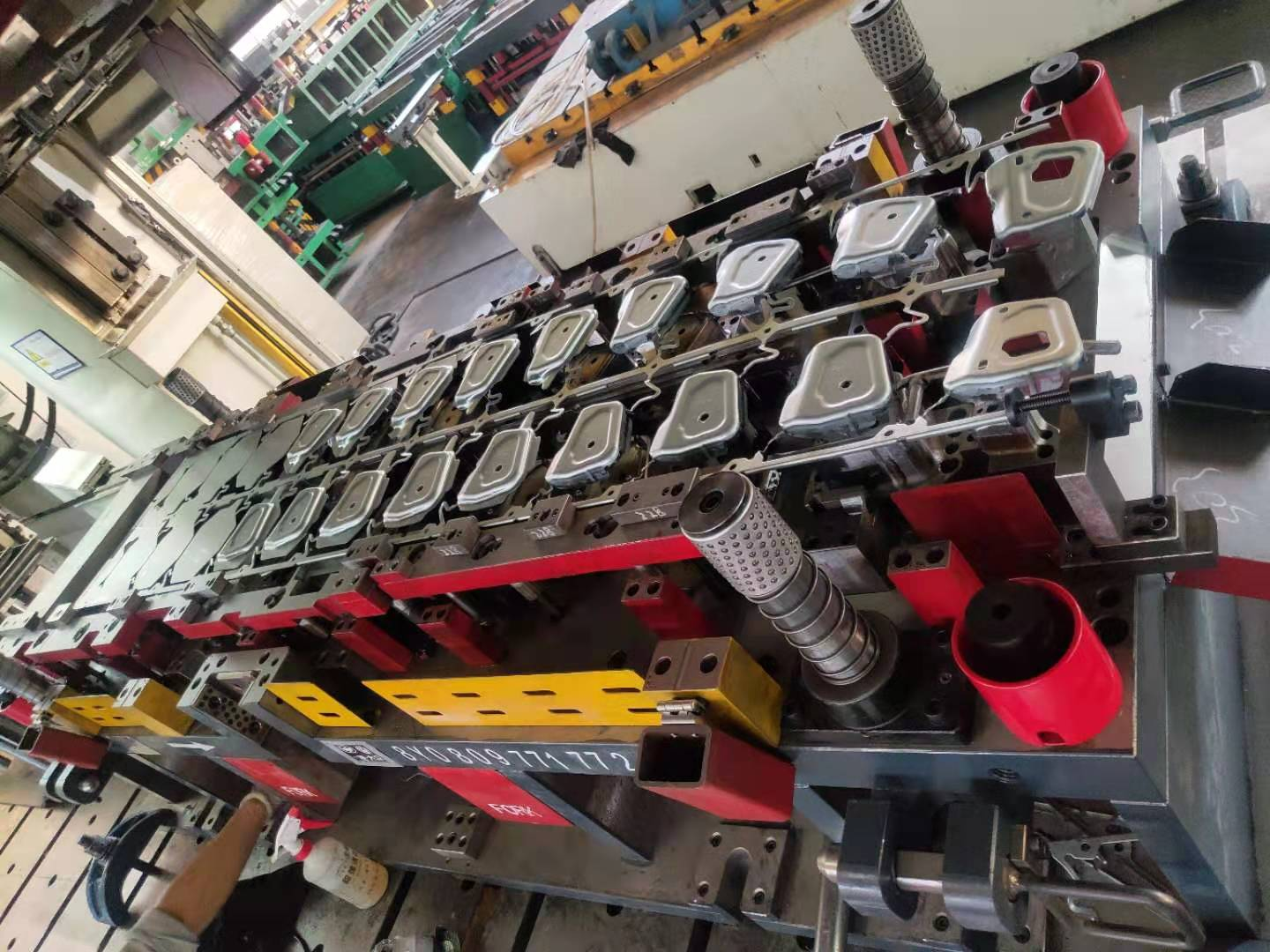

What are the methods to improve the durability of metal stamping dies

Because metal abrasives are often destroyed during processing and specifications are lost during work, it is not possible to consider production and production regulations. Therefore, it is important to improve the wear resistance of metal parts stamping die. Hardware mold manufacturers tell you that the methods to improve the wear resistance of hardware mold are generally the following categories:

1, improve the design of the hardware mold

Whether the stamping die design is effective is the basic to improve the wear resistance of the hardware die. Therefore, in the design of the hardware mold, we should adopt effective and preventive measures to deal with the adverse conditions in the formation of goods, in order to improve the wear resistance of the hardware mold. For example, the design scheme contains a small round hole in the service life of the hardware mold is generally the key to display information in the small round hole grinding tool seat. For this kind of metal material abrasives, the length of the small die frame should be reduced as far as possible in the scheme design, so as to improve the tensile strength. In addition, guide sleeve is also used to promote the maintenance of small die frame.

2, the appropriate choice of hardware mold raw materials

Different raw materials of metal molds have different compressive strength, ductility and wear resistance. The application of advanced raw materials under the necessary specifications can increase the wear resistance by several times. Therefore, in order to improve the wear resistance of metal material abrasives, it is necessary to choose good materials.

3. Effectively develop the forging and tempering treatment of hardware mold parts

In the selection of high-quality metal mold materials, according to the requirements of the same raw materials and materials with different characteristics to develop reasonable calcination and quenching is the first important way to improve the wear resistance of hardware mold. For example, in the whole process of quenching and tempering treatment, assuming that the production and production of overtemperature in the whole process of heating, the plasticity of the spring piece will not only be large, but also in the whole process of water cooling and heat dissipation, which is very simple to form deformation and cracking, thereby reducing the wear resistance. Therefore, in the production of hardware mold, we must effectively grasp the heat treatment method.

4, scientific arrangement of hardware mold production and processing technology and ensure the precision of production and processing

The production and processing precision of the hardware mold damages the wear resistance of the hardware mold very much. When the gap of the assembly line is not symmetrical in the punching die, the die core will be bitten to death under the effect of shear stress, which seriously damages the service life of the hardware mold. In addition, assuming that the appearance of metal abrasives is smooth, the wear resistance of metal abrasives will be reduced.

Therefore, in the production and production process, we must pay enough attention to the specifications of the hole, the flatness of the fulcrum surface of the mold base and the fixed fixed plate, the symmetry of the center interval of the metal mold and the guiding accuracy of the guide sleeve and the positioning pin. The higher the precision of the production and installation assembly line, the higher the surface roughness grade of the parts, the higher the wear resistance of the metal material abrasive tools.

5, the appropriate choice of punching machine

In order to improve the wear resistance of metal material abrasions, punch machines with higher precision and torsion stiffness should be selected. The tonnage of the punch machine should exceed 30% of the pressure of the stamping die. In general, the application of AC servo motor high-speed punch can be used to add several to several times the relativity of the use of grinding tools.

6. Effective application and maintenance of hardware molds

In order to improve the wear resistance of the hardware mold, the operator must reasonably use and maintain the hardware mold, and often repair the hardware mold, in order to prevent the ineffective hardware mold.

In other words, we sort out the common methods to improve the wear resistance of metal material abrasives, and the practical significance of improving the wear resistance, not only can improve the service life of metal material abrasives, reduce the production cost of wear-resistant material enterprises, but also can ensure the quality of the products produced and improve the yield.

推荐资讯 / Recommended News

Contact Us

Qingdao Yusen Precision Industry Co., Ltd

Contact person: manager Chen

Mobile: 18953226137

Email: quality@qdyusen.cn

business@qdyusen.cn

Address: Jiefang Third Road, Longquan automobile industry new town, Jimo District, Qingdao

CN

CN EN

EN